The Rise of the Robot Startups

Tue, 07/03/2018 - 12:00

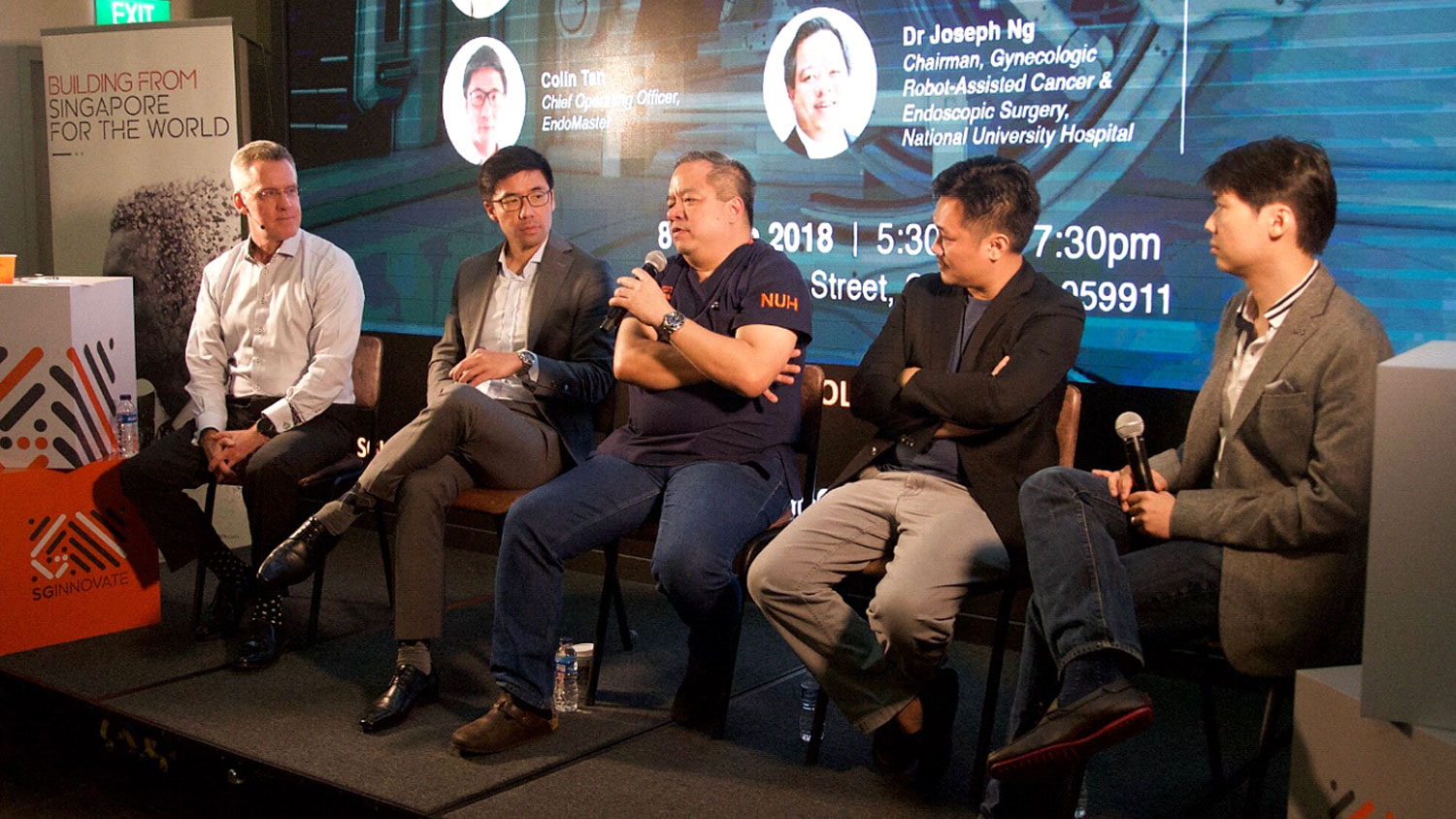

Starting a robotics company may seem like the coolest job in the world, but in reality requires a lot of grit and hard work, said a panel of experts.

Imagine a surgeon’s assistant who never feels sleepy, never suffers from tremors and never lets emotions get in the way of work.

Fortunately for surgeons, this miraculous being indeed exists in the form of the da Vinci surgical robot, now widely used to perform minimally invasive surgery in Singapore’s hospitals. Made by US company Intuitive, the robot is also a boon for patients, who recover much faster post-operation, said Dr Joseph Ng, chairman of the Gynaecologic Robot-Assisted Cancer & Endoscopic Surgery (GRACES) programme at Singapore’s National University Hospital.

For instance, while traditional surgery for endometrial cancer entails a six-day hospital stay and some 300 millilitres of blood loss in the hands of a good surgeon, a patient who undergoes robotic surgery can go home on the same day, and loses a tenth as much blood even if she is operated on by a trainee surgeon. “In the profession, we like to say that the robot makes a mediocre surgeon great, and takes a great surgeon to astronomical heights,” said Dr Ng.

An advocate for the use of robots in the operating room, Dr Ng was speaking at the SGInnovate panel discussion ‘Startup Stories Medical Robotics: From Project to Product to Company’. Moderated by SGInnovate founding CEO Mr Steve Leonard, the panel also comprised Mr Colin Tan, chief operating officer of medical robotics startup EndoMaster; Mr Jeff Tang, chief technology officer of home-grown engineering company HOPE Technik; and Dr Benjamin Tee, President’s Assistant Professor at the National University of Singapore and co-founder of medical device startup Privi Medical.

Hardware: harder than it looks

For surgeons like Dr Ng, robots are incredibly useful tools that augment human capabilities. But building an effective and safe robotic product is an extremely ambitious undertaking, said the panel. “Robotics may sound like such simple and sexy work, but there are many different engineering disciplines and a lot of hard work that go into it,” said Mr Tan of EndoMaster. The company, spun out of research at the National University of Singapore and Nanyang Technological University, is developing an endoscope with tiny robotic arms that can remove tumours in the gastrointestinal tract.

Mr Colin Tan, Chief Operating Officer of EndoMaster speaking at the panel discussion. On his left is SGInnovate’s CEO, Mr Steve Leonard

Mr Colin Tan, Chief Operating Officer of EndoMaster speaking at the panel discussion. On his left is SGInnovate’s CEO, Mr Steve Leonard

Unlike software products, which are easier and cheaper to build, test and iterate, robots also require the development of sophisticated hardware, which can be a challenge for small companies, said a member of the audience.

“Hardware necessarily dictates that you need a multidisciplinary team. Without access to different knowledge domains, building hardware is extremely difficult,” said Dr Tee, whose company Privi Medical has developed a device that uses cold compression to alleviate pain in people suffering from haemorrhoids. An academic and educator in addition to being a founder, Dr Tee added that wearing these different hats has indeed helped him to become a better innovator.

In addition to people with expertise in multiple disciplines, companies also need engineers with different working styles, said HOPE Technik’s Mr Tang. “You need certain types of people for different stages of product development. In the beginning, you need engineering ‘commandos’ who code in the worst way possible, who don't follow any process. Their code is a mess—it’s not documented and will never be maintainable. But that is what you need to get to a minimum viable product (MVP).”

Mr Jeff Tang, CTO of HOPE Technik, sharing his thoughts on getting to an MVP

Mr Jeff Tang, CTO of HOPE Technik, sharing his thoughts on getting to an MVP

The race to the MVP

The MVP, continued Mr Tang, doesn’t have to be perfect.

Your idea for a product may be fuzzy, but it’s actually wrong to have a concrete image in the beginning because you don’t know what your customer wants, and you don’t know what works.Jeff Tang

The hard work, he added, then comes in finding a client who is willing to provide you with an environment in which to test drive this MVP. “HOPE Technik is lucky—we have very good connections, and so we are able to find people who allow us to trial our products at very different stages of development,” he shared.

In this respect, startups may find willing partners in the medical community. “You’d be surprised at the crudity of a prototype that a surgeon will get excited about. I’m just going to put this out there—you don’t have to have a polished product,” quipped Dr Ng.

“A surgeon will look at [the prototype] and say ‘that could work’, and they would be happy to help you take the next step and share ideas with you. We really want to see technology, but the rate at which technology is being pushed out and the process by which this is done is frustrating,” added Dr Ng.

Dr Joseph Ng, Chairman of GRACES, NUH, shares his views as a medical professional

Short-circuiting the tech timeline

Part of this frustration, said the panel, stems from the eternal tug-of-war between innovators and medical regulators. While acknowledging that regulators have an important job to do, the panel also said that the time and investment needed to fulfil the current multitude of requirements poses a serious barrier to innovation. In the meantime, countries with less stringent regulatory environments, such as China, are leaping ahead.

While Singapore has built regulatory sandboxes for autonomous vehicles and fintech innovations, no equivalent exists for medical robotics, observed Dr Tee.

Dr Benjamin Tee, President’s Assistant Professor, NUS, suggests having regulatory sandboxes for medical robotics in Singapore

Dr Benjamin Tee, President’s Assistant Professor, NUS, suggests having regulatory sandboxes for medical robotics in Singapore

I think we need to think about providing some variation on the sandbox, in particular a place—which could be virtual—where doctors, entrepreneurs, innovators and creative types can meet and test out ideas very quickly.Dr Benjamin Tee

Bringing the discussion back to the idea of the MVP, Dr Ng pointed out that working with end-users to improve early, crude prototypes is one way to address the delays caused by regulation. “Not everybody is interested in a workable product right away. If you short-circuit that [development] process, whatever lead time you make up in the front end can be spent on the regulatory process.”

Dr Ng further challenged the audience to rethink the current process of technology development and regulation. “The process by which medical devices are evaluated is so ingrained, but does it really make a product safer? We don’t know, because nobody has really asked that question… this is an area that is prime for disruption.”

At SGInnovate, we love to bring together great minds across the ecosystem to discuss, share and inspire ideas of innovation in deep tech. Join our community to be the first to know about all our latest happenings!

Trending Posts

- How leaders should rethink cybersecurity strategy

- The future of fusion energy: What will it take to bring the power of the stars to earth?

- Keeping satellites safe: How CYSAT Asia 2026 is tackling space cybersecurity

- How an aerospace engineer charted a path to quantum technology

- Scaling nanomaterials is challenging — Meet the startup with a hybrid solution